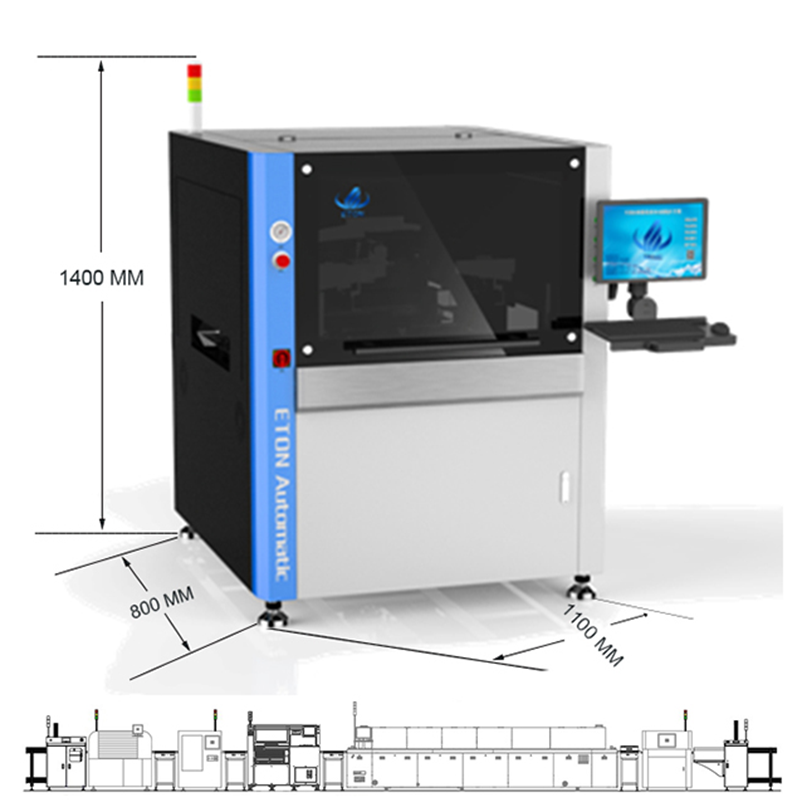

- Standard SMEMA link port.able to connect with most market smt machine.

- NC slide way adjustment for conveyor width and speed.

- SMEMA interface, able to connect with most market smt machine.

- Dry-type, wet-type and vacuum-type with arbitrary combination for stencil cleaning system.

- ETON self development Vision alignment system.

- Built-in software diagnosis system.

- Standard stainless steel squeegee, unique design to improve the lifespan of squeegee blade.

-

-

- Standard SMEMA link port.able to connect with most market smt machine.

- NC slide way adjustment for conveyor width and speed.

- SMEMA interface, able to connect with most market smt machine.

- Dry-type, wet-type and vacuum-type with arbitrary combination for stencil cleaning system.

- ETON self development Vision alignment system.

- Built-in software diagnosis system.

- Standard stainless steel squeegee, unique design to improve the lifespan of squeegee blade.

-

- The correction method adopts the movement of the net support arm to coordinate the X, Y, Z correction adjustment of the printed matter (platen), and the correction is convenient and simple.

- Using microcomputer PLC control,Human-machine interface touch control, Single/double printing and manual/semi-automatic modes can be selected.

- The squeegee seat can be adjusted back and forth, and the printing squeegee can be adjusted by ±15° according to the needs of product printing.

- Using air cylinder and magnetic proximity switch, the worktable reciprocates, the accuracy of the printing surface can reach ±0.01mm.

- Use air pressure 4-6kgf/cm², printing table area 320*500mm and printing accuracy ±0.02mm, machine repeat accuracy ±0.02mm.

- With automatic counting function and alarm times setting, convenient for output statistics.

- With the adjustment of the stopping time of the printing action, it is convenient to meet the production needs.

-

- The correction method adopts the movement of the net support arm to coordinate the X, Y, Z correction adjustment of the printed matter (platen), and the correction is convenient and simple.

- Using microcomputer PLC control,Human-machine interface touch control, Single/double printing and manual/semi-automatic modes can be selected.

- The squeegee seat can be adjusted back and forth, and the printing squeegee can be adjusted by ±15° according to the needs of product printing.

- Using air cylinder and magnetic proximity switch, the worktable reciprocates, the accuracy of the printing surface can reach ±0.01mm.

- Use air pressure 4-6kgf/cm², printing table area 320*500mm and printing accuracy ±0.02mm, machine repeat accuracy ±0.02mm.

- With automatic counting function and alarm times setting, convenient for output statistics.

- With the adjustment of the stopping time of the printing action, it is convenient to meet the production needs.

-

Set of stepper motor

Control Industrial control panel

One section of control, two Sensors

Set of electric control box

-

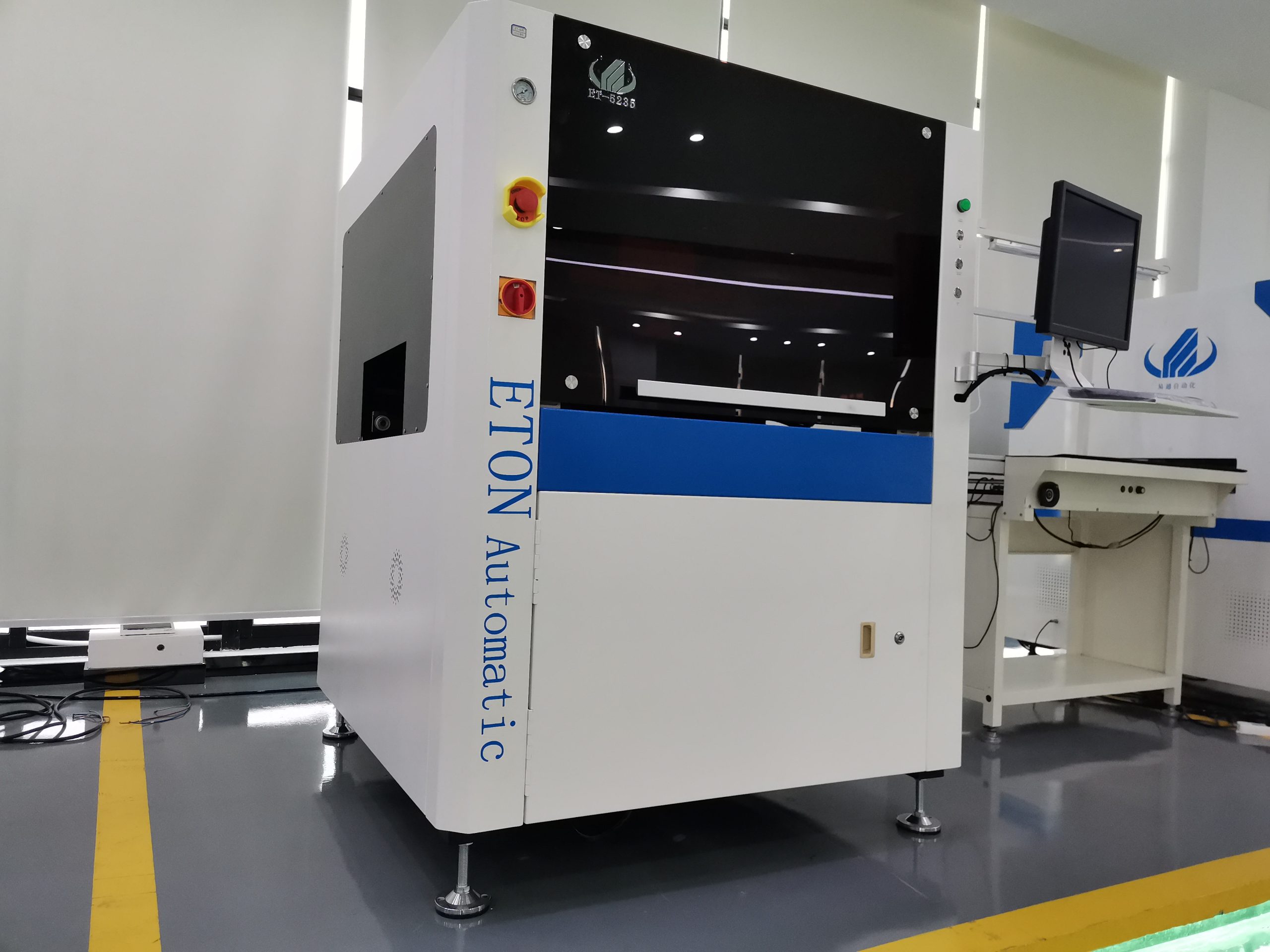

- Easy operation with Windows 7 system in Chinese and English language,

very convenient to use - 10 sets the high-resolution camera for accurate vision alignment correction

- a precision electric feeder with double motors

- Easy operation with Windows 7 system in Chinese and English language,

-

PCB transport and cleaning system

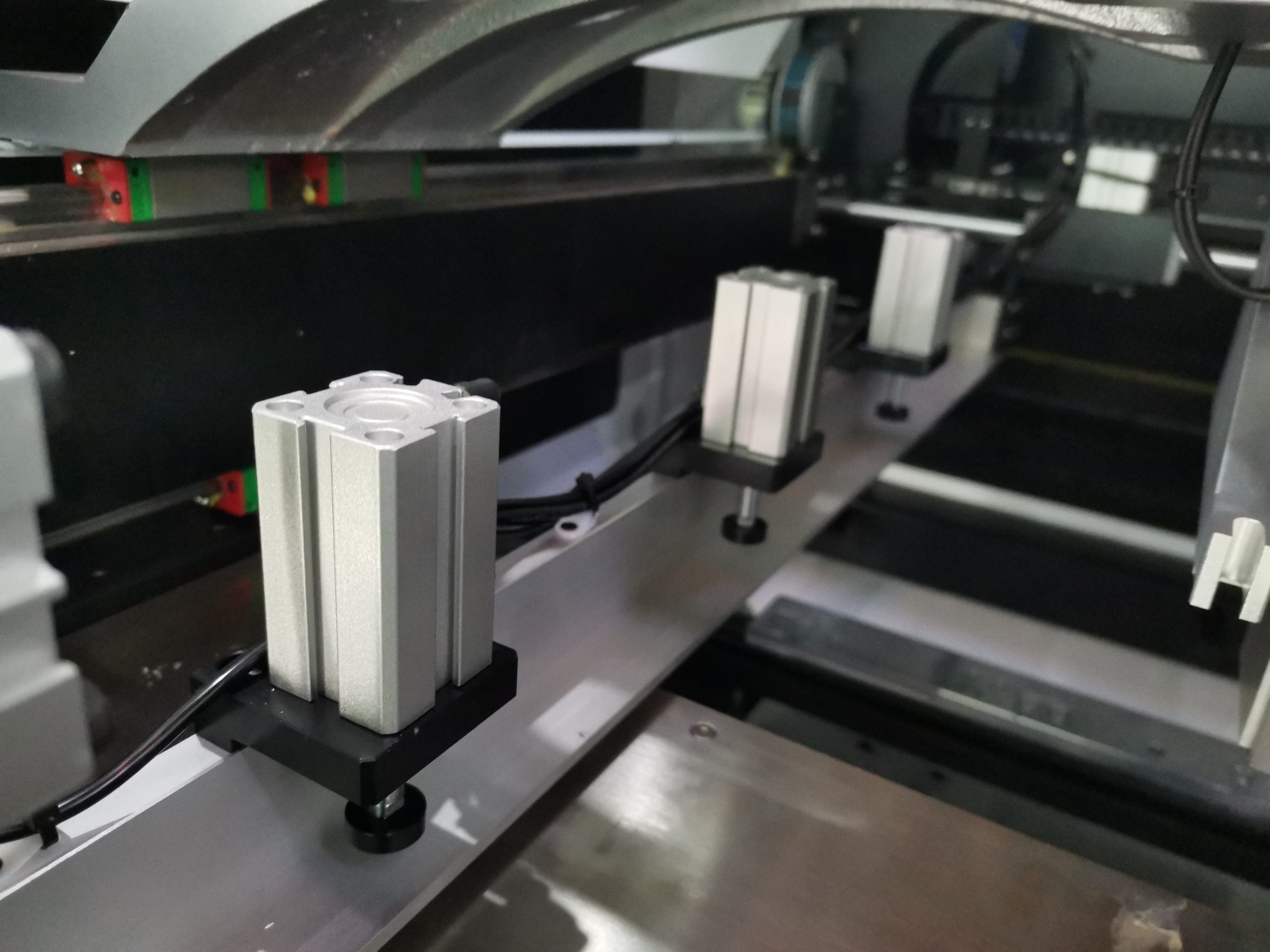

The PCB loading direction can be selected and combined freely.

Unique crafted internal gear conveyor belt to prevent jamming.

Programmable transport speed control makes PCB stop more precise

Adopt flexible side clamps and segmented supports to effectively clamp the РСВ to ensure a fully balanced contact between the РСВ and the steel mesh. -

PCB transport and cleaning system

The PCB loading direction can be selected and combined freely.

Unique crafted internal gear conveyor belt to prevent jamming.

Programmable transport speed control makes PCB stop more precise

Adopt flexible side clamps and segmented supports to effectively clamp the РСВ to ensure a fully balanced contact between the РСВ and the steel mesh. -

-

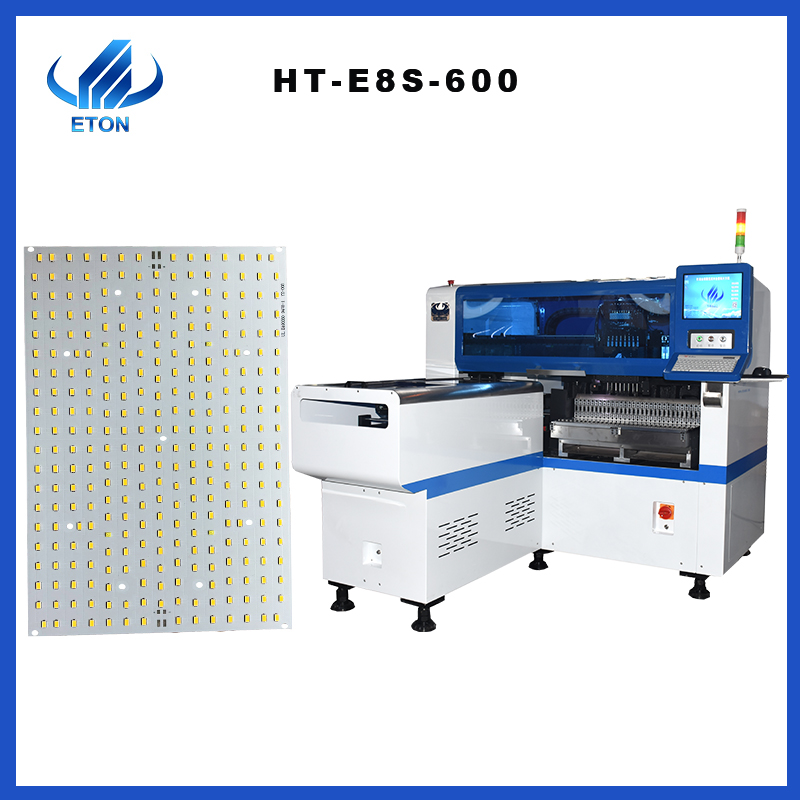

1.It has 12PCS head and the mounting speed can reach 45000CPH.

2.The maximum PCB size is 1200*500mm.Min size 0402.

3.Group picking and separately placing,separately picking and separately placing.

4.Vision alignment flight identification, Mark correction.

-

1.It has 12PCS head and the mounting speed can reach 45000CPH.

2.The maximum PCB size is 1200*500mm.Min size 0402.

3.Group picking and separately placing,separately picking and separately placing.

4.Vision alignment flight identification, Mark correction.

-

PCB Transport and Clamping system:the PCB loading direction can be selected and combined freely,unique crafted internal gear conveyor belt to prevent jamming, adopt flexible side clamps and segmented supports to effectively clamp the PCB to ensure a fully balanced contact between the PCB and the steel mesh