- X,Y,and Z axis all adopt self-developed high-end magnetic linear motor

-

Flexible PCB handling capabilities, multi-station,multi-material mounting

-

Y axis adopts double drive gantry structure

-

Support automatic replacement nozzle function(option)

-

Apply to 0201~40*40mm tape reel package and IC tray feeder

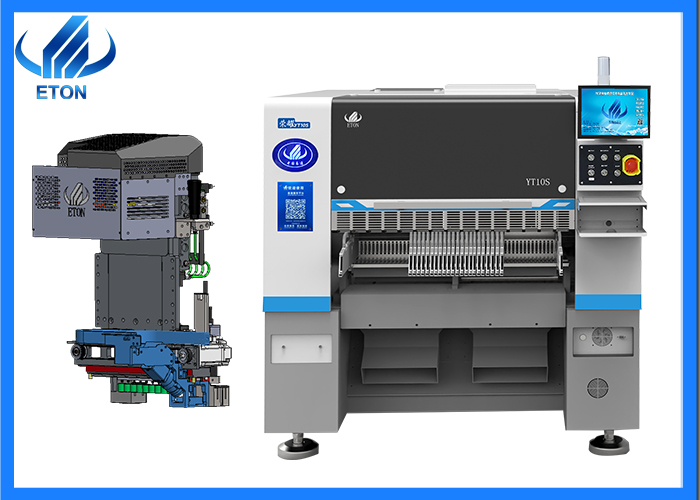

Pick and place machine 2000KG 48000 CPH for Flexible Production

Description

Machine main features

1.X,Y,and Z axis all adopt self-developed high-end magnetic linear motor

2.Flexible PCB handling capabilities, multi-station,multi-material mounting

3.Y axis adopts double drive gantry structure

4.Support automatic replacement nozzle function(option)

5.Apply to 0201~40*40mm tape reel package and IC tray feeder

- Brand new self-developed high-precision placement head.

- Combininghigh-accuracy mark recognition camera with a fixed-flight vision camera to ensure placement accuracy.

- The placement head adopt independent vacuum detection,improve placement performance.

- Off-line programming,saves time during changeover cycles.

- The software includes Al Deep Learningand Automatic Optimization functions.

- Supports providing an MES system interface.

- Equipped with coordinate import function.

Machine main parameter

|

Model |

YT10S |

|

Dimension |

|

|

Length |

1480mm |

|

Width |

2020mm |

|

Height |

1650mm |

|

Total Weight |

2000kg |

|

PCB |

|

|

PCB Length Width |

Max:500*450mm(1200*450 option) Min:50*50mm |

|

PCB Thickness |

0.5-5mm |

|

PCB Clamping |

Cylinder clamping, track width adjustable |

|

Mounting Mode |

Group picking and separate placing\separate picking and separate placing |

|

O.S. |

|

|

System |

Windows7 |

|

Software |

R&D independently |

|

Display |

LED monitor |

|

Input Device |

Keyboard, Mouse |

|

Vision System |

|

|

No. of Camera |

1 PCS (Head flight vision camera) |

|

2 PCS Mark camera |

|

|

Mounting Precision |

CHIP±0.03mm QFP±0.025mm Cpk ≧1.0 (3σ) |

|

Mounting Height |

≦16mm(Other height can be customized) |

|

Mounting Speed |

48000 CPH(Under best condition) |

|

Components |

0201~15MM packaging material and IC material(Optional fixed camera for 0201~35*35MM), Other component size can be customized |

|

Components Space |

0.2mm |

|

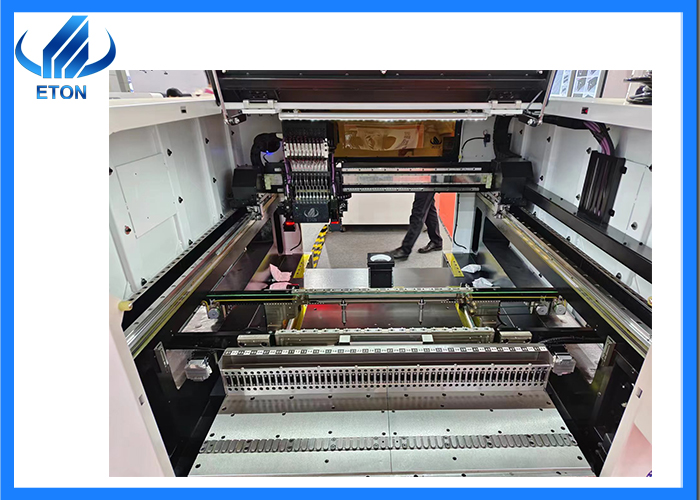

No. of Feeders Station |

52 PCS (104 PCS option) |

|

No. of nozzles |

10 PCS |

|

Power |

220AC 50HZ |

|

Power Consumption |

1.5kw |

|

Operating Environment |

23℃±3℃ |

|

Transmission Speed |

>1000mm/sec |

|

Transmission Direction |

Single(left→ right or right→ left) |

|

Transmission Mode |

Online drive |

|

Position Mode |

Optical |

|

Gas consumption |

0.4-0.6mpa (4-6kgf/cm2)600N/min |

|

Electrical control |

Independent research and development by ETON |

|

Motion control card module 1 set |

Independent research and development by ETON |

|

X,Y,Z Axis Drive way |

High-end magnetic linear motor |

|

Feeding way |

Intelligent feeder with double motor |

|

Production management MES system interface |

Customized |

Our advantage

ETON is the pioneer of SMT machine field in China which have more than 20 years experiences. And owned CCC, SIRA, CE certificates with 14 invention patents, 135 practical patents, 55 software copyrights of intellectual property technologies.

Oversea market

The products exported to more than 30 countries and regions, including South Korea, India, Vietnam, Tunisia, Egypt,Turkey, Russia, Brazil etc.

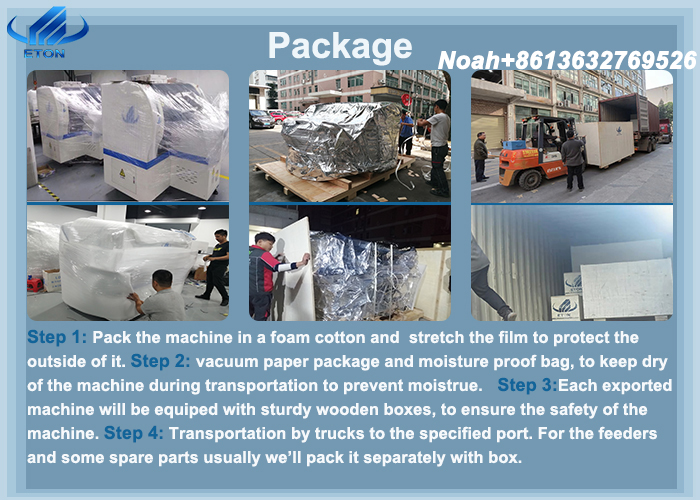

Packages

Keep a good quality of the machine when during transportation till the destination of our clients which is an imperative aspect for one of a suitable service for our clients to buy our machine, so making sure of a qualified and sturdy packing is a key mission for us, here are the specified steps for your reference:

Service

Pre-sale service

Provide suitable production plan

Advise on plant electrical equipment and layout

Sale service

Report machine status in time

Follow up and send test machine video

After-sales service

Software lifetime upgrade

24 hours to deal with problems online

Engineers can arrive on site to teach operation and debug the machine

Regular visit (one year warranty period, spare parts repair free; Once or twice a year after warranty)

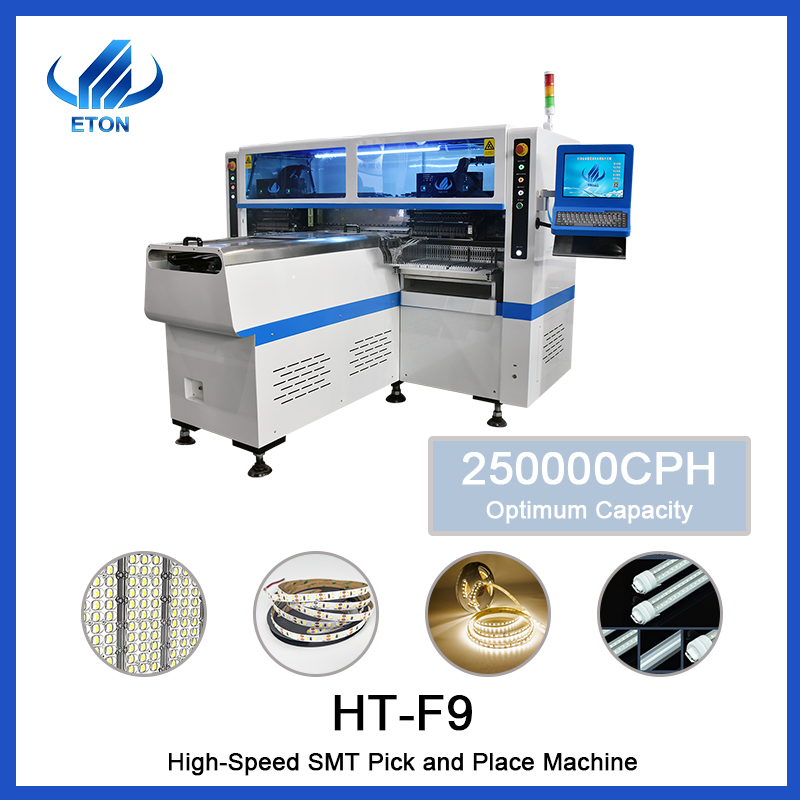

Related machine

We can provide a whole SMT production line,led light production line:

- Pick and place machine

- Loader machine

- Conveyor machine

- Stencil printer machine

- Reflow oven machine

- Unloader machine

- Solder paste mixer

- Roll to roll led strip light assembly machine

FAQ

- Can I go and see if you have sold the equipment to India?

- Yes, we have sold our machine in India, but for the fact we can’t decide it for my customer, but I will try to contact my customer. Hope you can understand, because no one wants their competitors to visit their manufacturing site.

- Is the machine easy to operate?

- Yes, our machine is very intelligent and easy to operate, like the intelligent phone, also the software is made by our company, so we know how to make it more intelligent and operate friendly.

Contact me

Whatsapp/Wechat: +8613632769526

Email: Noah@eton-mounter.com